What is the total performance of acrylic material?

First.What is acrylic material?

ACRYLIC, also known as PMMA or Acrylic, Acrylic.

The chemical name is polymethyl methacrylate. From English Organic Glass, it means a PMMA board made of MMA of organic compound, which has transparency and transparency like glass. Acrylic is an important thermoplastic that was developed earlier.

Acrylic products include acrylic sheets, acrylic plastic pellets, acrylic light boxes, signboards, acrylic bathtubs, acrylic artificial marbles, acrylic resins, acrylic (lacquer) paints, etc., and a wide variety. The acrylic products commonly used are made of acrylic pellets, plates or resins and other raw materials, and assembled with various materials and functional parts. Acrylic fiber, acrylic cotton, acrylic yarn, acrylic nylon, etc., which are commonly heard, are man-made fibers polymerized from acrylic acid and are not associated with acrylic products.

Second.the main use of acrylic materials

Do you know anything about acrylic? I believe you generally know. Let's take a look at the use of acrylic materials.

PMMA is a polymer obtained by polymerizing acrylic acid and its esters, collectively referred to as acrylic resin. The corresponding plastics are collectively referred to as polyacrylic plastics, of which polymethyl methacrylate is the most widely used. Polymethyl methacrylate, abbreviated as PMMA, commonly known as plexiglass, is by far the most excellent synthetic transparent material.

PMMA has the advantages of light weight, low cost and easy molding. Its molding methods include casting, injection molding, machining, and thermoforming. In particular, injection molding can be mass-produced, with simple process and low cost. Therefore, its application is increasingly widespread, it is widely used in instrumentation parts, automotive lights, optical lenses, transparent pipes and so on.

Application areas:

1.Building applications: window, soundproof windows and doors, lighting hood, telephone booth, etc.

2.Advertising applications: light boxes, signs, signs, display racks, etc.

3.Traffic applications: trains, cars and other vehicle doors and windows, etc.

4.Medical applications: baby incubators, all kinds of surgical medical equipment, civilian supplies: bathroom facilities, crafts, cosmetics, stents, aquariums, etc.

5.Industrial applications: instrument surface plates and covers, etc.

6.Lighting applications: fluorescent lamps, chandeliers, street lamp covers, etc.

Application areas: hotels, shopping malls, office buildings, clubs, villas, museums, medical, education, catering, exhibitions, etc.

Application areas: ceilings, integrated ceilings, partitions, screens, sliding doors, transparent walls, hotel furniture, office furniture, bar counters, lighting, chandeliers, signs, signs, floors, landscapes, etc.

Third. the advantages and disadvantages of acrylic materials

Advantages: Acrylic is the best new material that can be used to make sanitary ware after ceramics. Compared with traditional ceramic materials, acrylic has the following advantages in addition to unparalleled high brightness: good toughness and not easy to break; strong repairability, just use a soft foam to remove the toothpaste to wipe the sanitary ware; soft texture, winter There is no sense of cold and biting; the color is bright, which can satisfy the individual pursuit of different tastes. Acrylic basins, bathtubs and toilets are made of acrylic, which are not only beautiful in style, durable, but also environmentally friendly. Their radiation levels are similar to those of the human body. Acrylic sanitary ware first appeared in the United States and has occupied more than 70% of the entire international market.

Disadvantages: Because acrylic production is difficult and costly, there are many low-cost and low-cost substitutes on the market. These substitutes are also known as "acrylic" and are actually ordinary organic boards or composite boards (also known as sandwich panels). Ordinary organic plates are cast with common plexiglass cracking materials and pigments. The surface hardness is low and easy to fade. After polishing with fine sand, the polishing effect is poor. The composite board has only a thin layer of acrylic on the surface, and the middle is ABS plastic, which is easily delaminated by the expansion and contraction during use. True and false acrylic can be identified from the subtle chromatic aberration and polishing effect of the sheet section.

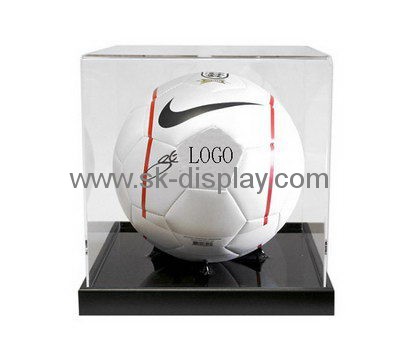

Acrylic display stand is also a high-end display stand that has recently emerged. Its comprehensive performance is far higher than other materials, but there are many inferior and counterfeit acrylic materials on the market. Customers should judge or look for more when customizing the acrylic display stand. Good display stand brand!

For more information about acrylic displays, welcome to visit professional Chinese acrylic displays manufacturer website: https://www.sk-display.com